Home

Home

Check out the Zoeller YouTube Channel for tips, training, and product videos!

X

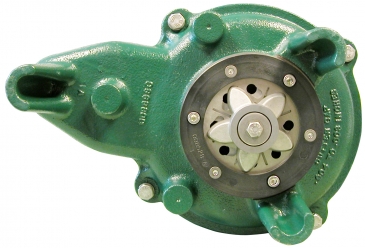

7011 Reversing Grinder Pump

7011 Reversing Grinder Pump

Application- Commercial Buildings

2 HP reversible grinder pump

-

Features and Benefits

APPLICATIONS

- Pumping stations

- Housing developments

- Pressure sewers

SPECIFICATIONS

- Discharge: 1-1/4″ NPT Vertical or Horizontal

- Durable, heavy-duty finned cast iron construction

- 1 Phase – integral thermal overload

- 3 Phase – thermal sensor and leads

- Corrosion-resistant, powder coated epoxy finish

- Oil-filled, hermetically sealed motor with Class F insulation

- Hardened stainless steel cutter and disc

- Cutters protected from abrasive solids

- Cutters can automatically alternate direction to enhance blade life and free hang-ups (automatic or manual)

- Stainless steel screws, bolts, and lifting bail

- Easily adapts to many existing competitors’ rail systems

- Mechanical shaft seals with leak detection – carbon/silicon carbide lower seal, carbon/ceramic upper seal

- Viton O-rings

- Automatic thermal overload protection (1 Ph)

- Thermal sensor protection (standard on 3 Ph)

- Legs provide for free-standing installation

- Preassembled systems available

Note: Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

-

Product Specifications

Voltage Ability 200 / 230 / 460 Phase 1 & 3 Hz 60 Discharge Size 1.25″ Solids Handling Grinder, Slurry HP 2 RPM 3450 Seals Upper – Carbon Ceramic

Lower – Silicon Carbide/CarbonO Rings Viton Impeller Ductile Iron Vortex - Technical Data

-

Literature

- Tech Data & Performance Curves, 7011 / 7013 ZM1288

- Dimensional Data, 7011 / 7013 ZM2625

- Simplex Grinder System Layout ZM1910

- Owner’s Manual, 7011 / 7013 ZM2609: 60 Hz

- Parts List, 7011 ZM2634

- Guide Spec, 7011 ZM1724

- Sales Slick, (X)7011 / (X)7013 ZM3134

- Dimensional Data, 7011 / 7013 Horizontal Discharge ZM3410

APPLICATIONS

- Pumping stations

- Housing developments

- Pressure sewers

SPECIFICATIONS

- Discharge: 1-1/4″ NPT Vertical or Horizontal

- Durable, heavy-duty finned cast iron construction

- 1 Phase – integral thermal overload

- 3 Phase – thermal sensor and leads

- Corrosion-resistant, powder coated epoxy finish

- Oil-filled, hermetically sealed motor with Class F insulation

- Hardened stainless steel cutter and disc

- Cutters protected from abrasive solids

- Cutters can automatically alternate direction to enhance blade life and free hang-ups (automatic or manual)

- Stainless steel screws, bolts, and lifting bail

- Easily adapts to many existing competitors’ rail systems

- Mechanical shaft seals with leak detection – carbon/silicon carbide lower seal, carbon/ceramic upper seal

- Viton O-rings

- Automatic thermal overload protection (1 Ph)

- Thermal sensor protection (standard on 3 Ph)

- Legs provide for free-standing installation

- Preassembled systems available

Note: Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

| Voltage Ability | 200 / 230 / 460 |

| Phase | 1 & 3 |

| Hz | 60 |

| Discharge Size | 1.25″ |

| Solids Handling | Grinder, Slurry |

| HP | 2 |

| RPM | 3450 |

| Seals | Upper – Carbon Ceramic Lower – Silicon Carbide/Carbon |

| O Rings | Viton |

| Impeller | Ductile Iron Vortex |

Pump Performance Curves

Design Tools

- Tech Data & Performance Curves, 7011 / 7013 ZM1288

- Dimensional Data, 7011 / 7013 ZM2625

- Simplex Grinder System Layout ZM1910

- Owner’s Manual, 7011 / 7013 ZM2609: 60 Hz

- Parts List, 7011 ZM2634

- Guide Spec, 7011 ZM1724

- Sales Slick, (X)7011 / (X)7013 ZM3134

- Dimensional Data, 7011 / 7013 Horizontal Discharge ZM3410