Home

Home

Check out the Zoeller YouTube Channel for tips, training, and product videos!

7020, 7021 Grinder Pumps

7020, 7021 Grinder Pumps

Application- Commercial Buildings

Progressing cavity grinder pumps

-

Features and Benefits

APPLICATIONS

- Sanitary sewage pumping stations

- Pressure sewage systems

- Commercial and residential sewage removal

SPECIFICATIONS

PUMP:

- Discharge: 1-1/4” NPT horizontal

- Seals – Silicon Carbide/Carbon, Buna-N elastomers

- Construction – motor housing, cover, adapter and pump housing cast iron ASTMA A-48, corrosion-resistant, powder coated epoxy finish

- Attaching hardware – 304 stainless steel

- Square ring and gasket – Viton

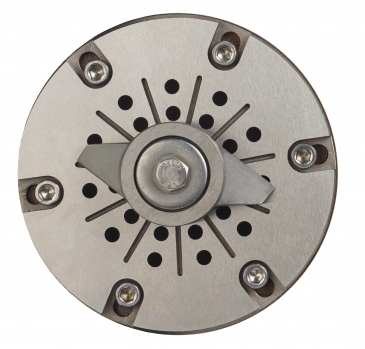

- Stainless steel cutter and plate hardened to Rockwell C 55-60

- Pressure relief valve

- Stainless steel legs provide for free-standing installation

- Stainless steel helix hydraulic rotor

- Buna-N hydraulic stator

MOTOR:

- Permanent split capacitor (PSC) motor

- Stator – Class B insulation and lead wires, Nema B design

- Integral thermal overload protection with automatic reset

- Housing – Finned cast iron, oil-filled

- 416 stainless steel motor shaft

- Upper and lower ball bearings – dual, high carbon chromium steel

- 20′ (6 m) power cord with 15 amp plug (extended cord lengths available)

Note: Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

-

Product Specifications

Voltage Ability 230 or 200 (2 HP Only) Phase 1 Hz 60 Discharge Size 1.25″ Solids Handling Grinder, Slurry HP 1 & 2 RPM 1750 Seals Silicon Carbide/Carbon O Rings Viton Impeller Hydraulic Rotor -

Technical Data

Caution

To ensure proper pump operation, a swing or flapper style check valve must be installed in the pump discharge line. A faulty or non-functional check valve when combined with a pressure may prevent the pump from starting.

Pump Performance Curves

Design Tools

-

Literature

- Tech Data & Performance Curves, 7020 & 7021 ZM2424: 60 Hz

- Simplex Grinder System Layout ZM1910

- Owner’s Manual, 7020 & 7021 ZM2607: 60 Hz

- Repair Manual, 7020 & 7021 ZM3208

- Parts List, 7020 ZM2637

- Parts List, 7021 ZM2638

- Guide Spec, 7020 & 7021 ZM2416

- Sales Slick, 7020-7021 ZM3133

- Guide Specification Models 7020 & 7021 ZM2416

- Sales Slick, No Flush Zone, ZM3440

APPLICATIONS

- Sanitary sewage pumping stations

- Pressure sewage systems

- Commercial and residential sewage removal

SPECIFICATIONS

PUMP:

- Discharge: 1-1/4” NPT horizontal

- Seals – Silicon Carbide/Carbon, Buna-N elastomers

- Construction – motor housing, cover, adapter and pump housing cast iron ASTMA A-48, corrosion-resistant, powder coated epoxy finish

- Attaching hardware – 304 stainless steel

- Square ring and gasket – Viton

- Stainless steel cutter and plate hardened to Rockwell C 55-60

- Pressure relief valve

- Stainless steel legs provide for free-standing installation

- Stainless steel helix hydraulic rotor

- Buna-N hydraulic stator

MOTOR:

- Permanent split capacitor (PSC) motor

- Stator – Class B insulation and lead wires, Nema B design

- Integral thermal overload protection with automatic reset

- Housing – Finned cast iron, oil-filled

- 416 stainless steel motor shaft

- Upper and lower ball bearings – dual, high carbon chromium steel

- 20′ (6 m) power cord with 15 amp plug (extended cord lengths available)

Note: Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

| Voltage Ability | 230 or 200 (2 HP Only) |

| Phase | 1 |

| Hz | 60 |

| Discharge Size | 1.25″ |

| Solids Handling | Grinder, Slurry |

| HP | 1 & 2 |

| RPM | 1750 |

| Seals | Silicon Carbide/Carbon |

| O Rings | Viton |

| Impeller | Hydraulic Rotor |

Caution

To ensure proper pump operation, a swing or flapper style check valve must be installed in the pump discharge line. A faulty or non-functional check valve when combined with a pressure may prevent the pump from starting.

Pump Performance Curves

Design Tools

- Tech Data & Performance Curves, 7020 & 7021 ZM2424: 60 Hz

- Simplex Grinder System Layout ZM1910

- Owner’s Manual, 7020 & 7021 ZM2607: 60 Hz

- Repair Manual, 7020 & 7021 ZM3208

- Parts List, 7020 ZM2637

- Parts List, 7021 ZM2638

- Guide Spec, 7020 & 7021 ZM2416

- Sales Slick, 7020-7021 ZM3133

- Guide Specification Models 7020 & 7021 ZM2416

- Sales Slick, No Flush Zone, ZM3440